|

Integrating ionisation smoke detector

Available in the

Series 60 and

Series 65

ranges, this type of detector works on the same principles as

the ionisation smoke detector, but has modified signal

processing circuitry which allows an alarm threshold to be

present for up to 20 seconds without initiating an alarm.

This type of detector is suitable for use in

areas where transient high levels of smoke may be expected.

Integrating effect in analogue addressable systems

In

XP95

systems, the integrating effect can be mimicked in both

ionisation and optical smoke detectors by adjusting the

control equipment software to cause an appropriate delay.

Discovery

smoke detectors should be set to Mode 2 or Mode 4 to achieve

this effect. Click

here

to find out more.

Optical (photo-electric)

smoke detector

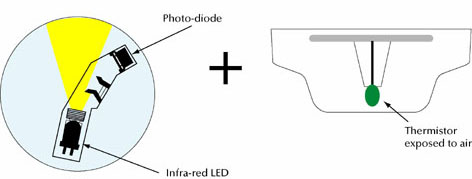

Optical smoke

detectors incorporate a pulsing infra-red LED located in a

chamber within the housing of the detector. The chamber is

designed to exclude light from any external source. At an

angle to the LED is a photo-diode which normally does not

register the column of light emitted by the LED. In the event

of smoke from a fire entering the chamber, the light pulse

from the LED will be scattered and hence registered by the

photo-diode. If the photo-diode "sees" smoke on the two

following pulses, the detector changes into alarm state and

the indicator LED lights up. The detector housing is identical

to that of the ionisation detector but has an indicator LED

which is clear in quiescent state but produces red light in

alarm.

Optical smoke detectors respond particularly

well to slow-burning (smouldering) fires. They are widely used

for life protection.

Heat detector

Most

conventional heat detectors (all Series 60 and

Series 65

&

AlarmSense

A1R, BR and CR) operate by using a matched pair of thermistors

to sense heat. One thermistor is exposed to the ambient

temperature, the other is sealed. In normal conditions the two

thermistors register similar temperatures, but, on the

development of a fire, the temperature recorded by the exposed

thermistor will increase rapidly, resulting in an imbalance of

the thermistors, causing the detector to change into alarm

state. Rate-of-rise detectors are designed to detect a fire as

the temperature increases, but they also have a fixed upper

limit at which the detector will go into alarm if the rate of

temperature increase has been too slow to trigger the detector

earlier.

The Series 65

and AlarmSense CS (static response) heat detectors have only

one thermistor. They change to the alarm state at a preset

temperature.

Externally, the heat detectors are

distinguishable from the smoke detectors by having wide

openings to the surrounding atmosphere to allow good movement

of air around the external thermistor.

A heat detector may be more appropriate than a

smoke detector where the environment is dirty or smoky under

normal conditions. It must be recognised, however, that any

heat detector will respond only when a fire is well

established and generating a high heat output.

Multisensor detector

Available in

the

XP95

and

Discovery

ranges, this type of detector is basically an optical smoke

detector - so it will respond well to smouldering fires. The

addition of a heat sensing element allows the multi-sensor to

give a response to fast burning (flaming) fires which is

comparable to that of an ionisation detector.

Multisensor detectors are general purpose

detectors which respond well to a wide range of fires.

Carbon Monoxide (CO) detector

Carbon Monoxide (CO) is a poisonous gas produced by combustion

and a CO fire detector is used to indicate the outbreak of a

fire by sensing the level of CO in the air. The detector has

an electrochemical cell which senses CO, but not smoke or

other combustion products. The cells do not require much power,

so the detector can be made electrically compatible with

ordinary smoke and heat detectors. Apollo manufacturers a CO

detector as part of the

Discovery

range.

CO detectors are particuarly good at detecting

deep-seated, smouldering fires.

To find out

more, visit the

CO Detectors

page.

Beam detector

A beam detector is

designed to protect large, open spaces and is made up of three

main parts: the transmitter, which projects a beam of infra-red

light; the receiver which registers the light and produces an

electrical signal; and the interface, which processes the

signal and generates alarm or fault signals. When a fire

develops, smoke particles obstruct the beam of light and, once

a pre-set threshold has been exceeded, the detector will go

into alarm.

To find out

more, visit the

XP95 Beam Detector

page.

Flame detector

A flame

detector is designed to detect either ultraviolet (UV) or

infra-red (IR) radiation emitted by a fire. The XP95

Dual IR flame detector

is sensitive to low-frequency, flickering infra-red radiation.

This means that the detector can operate even if the lens is

contaminated by a layer of oil, dust, water vapour or ice.

Flame detectors are

effective in protecting areas where flaming fires may be

expected.

To find out

more, visit the XP95

Dual IR Flame Detector

page.

Relative performance of Apollo

detectors in test fire

|

Type of

detector |

|

Type of

combustion | |

|

|

|

|

|

|

Overheating/thermal |

poor |

very good |

very good |

very poor |

very poor |

|

Smouldering/glowing |

moderate/good |

good |

good |

very poor |

excellent |

|

Flaming |

very good |

good |

good |

poor |

poor |

|

Flaming with high

heat output |

very good |

good

|

very good |

moderate/good |

moderate |

|

Flaming - clean

burning |

poor |

very poor |

moderate/good |

moderate/good |

very poor |

For

definitions of terms used within the fire detection industry,

visit the

Glossary.

|